Today’s built environment demands more than functional systems.

We face:

Optimisation isn’t just about fixing problems; it’s about proactively finding the best possible solutions across the entire project lifecycle, leading to superior performance, reduced impact, and greater ROI.

We leverage advanced engineering optimisation to empower your projects with intelligent design, sustainable solutions, and disciplined execution.

to

to

It's the systematic, data-driven process of identifying the most effective combination of design variables, operating parameters, and strategic decisions for MEP systems to achieve defined objectives (e.g., minimum energy consumption, maximum occupant comfort, lowest lifecycle cost) while adhering to all constraints (e.g., budget, space, codes, performance).

We employ rigorous mathematical modelling, simulation, and advanced algorithms to explore a vast solution space and pinpoint truly optimal configurations far beyond what traditional methods can achieve.

Optimising Mechanical, Electrical, and Plumbing (MEP) systems for peak efficiency, sustainability, and project success.

◦ Minimise energy bills and operational expenses.

◦ Optimise material use and reduce waste.

◦ Lower maintenance costs through optimised system design.

◦ Improve system reliability and longevity.

◦ Maximise occupant comfort and indoor environmental quality.

◦ Ensure compliance with performance targets.

◦ Identify and resolve design conflicts early (e.g., via BIM).

◦ Ensure compliance with complex regulations and standards.

◦ Reduce rework and costly change orders during construction.

◦ Explore novel, high-performing design solutions.

◦ Achieve industry leadership in sustainability and efficiency.

◦ Accelerate project timelines through streamlined design processes.

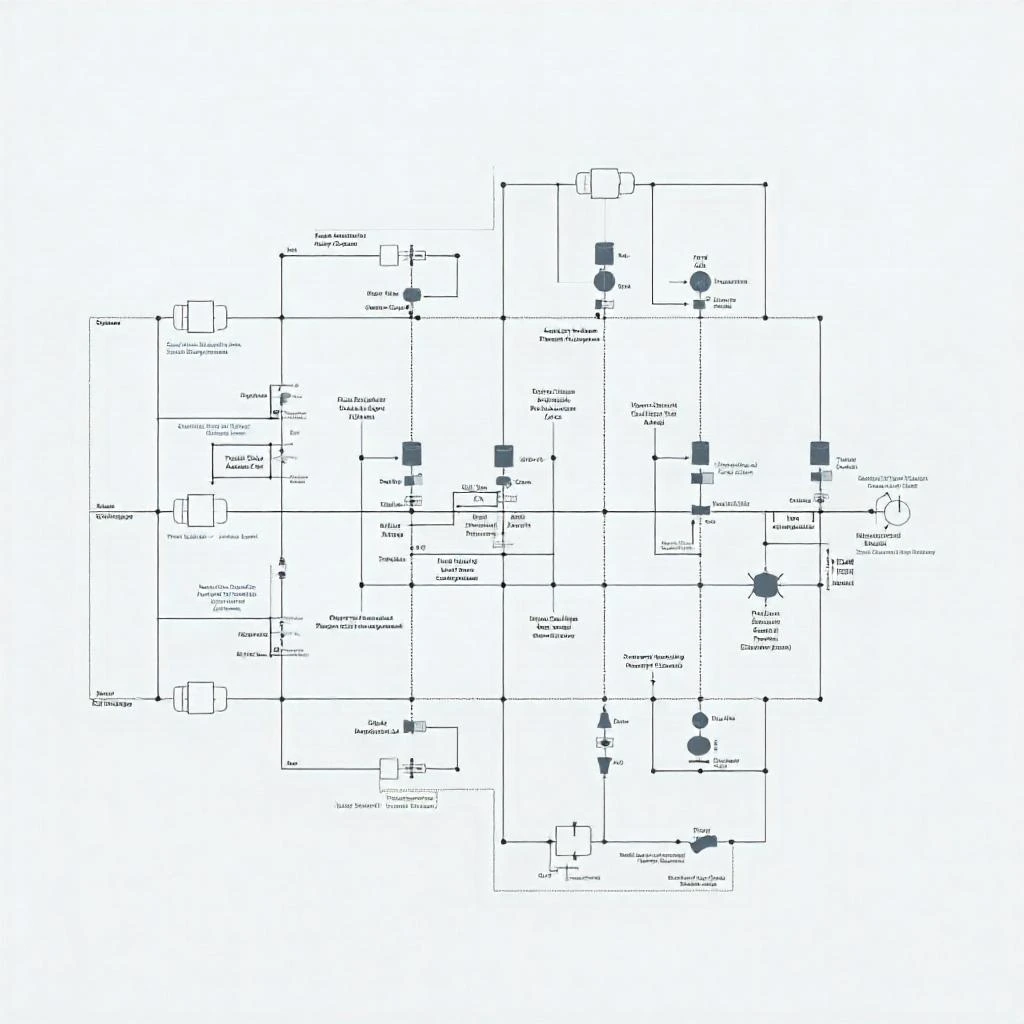

◦ Problem Formulation: Clearly define objectives, variables, and constraints (e.g., energy targets, budget, space limitations).

◦ System Modeling: Develop accurate digital representations of MEP systems and their interactions (e.g., energy models, CFD, BIM).

◦ Algorithm Application: Employ advanced optimisation techniques (e.g., multi-objective optimisation, genetic algorithms, simulation-based optimisation) to identify optimal solutions.

◦ Solution Analysis & Recommendation: Interpret results, quantify benefits, and provide actionable design and operational recommendations.

◦ Sustainable Design Integration: Embed sustainability from concept to commissioning – considering materials, carbon footprint, and resource use.

◦ Renewable Energy Feasibility: Assess and integrate solar PV, geothermal, wind, and other clean energy technologies.

◦ Water Conservation Strategies: Implement greywater, rainwater harvesting, and highly efficient plumbing systems.

◦ Green Building Certifications: Guide projects to achieve LEED, WELL, EDGE, and other relevant certifications.

◦ Advanced Energy Modeling: Precisely predict building energy performance and identify impactful Energy Conservation Measures (ECMs).

◦ Load Reduction First: Prioritise passive design, envelope optimisation, and efficient lighting to reduce energy demand before sizing active systems.

◦ High-Efficiency MEP Systems: Specify and optimise the selection of HVAC, lighting, and power equipment for peak performance and minimal consumption.

◦ Smart Controls & BAS Integration: Design intelligent Building Automation Systems (BAS) for dynamic control, fault detection, and continuous optimisation.

◦ Early Engagement & Coordination: Drive optimisation from schematic design through detailed engineering, ensuring seamless integration across disciplines.

◦ Budget & Value Engineering: Balance performance goals with cost-effectiveness, identifying high-value solutions.

◦ Risk Management: Proactively identify and mitigate technical, schedule, and cost risks.

◦ Clear Deliverables & Communication: Provide transparent reporting and detailed documentation, and maintain open communication channels with all stakeholders.

From Concept to Commissioning

◦ Client Needs Analysis, Data Collection, Stakeholder Interviews.

◦ Define Project Objectives, Constraints, and Success Metrics.

- Develop Detailed MEP Models (Energy, CFD, System Sizing).

- Run Optimization Simulations & Sensitivity Analysis.

- Identify Optimal Design Parameters and Operational Strategies.

- Generate Actionable Recommendations for MEP Systems.

- Collaborate with Design Teams for Integration into Drawings & Specifications.

- Quantify Expected Energy Savings, Cost Benefits, and Environmental Impact.

- Provide Technical Guidance During Construction.

- Support Commissioning to Ensure Systems Perform as Designed.

- Assist in Setting Up Post-Occupancy Performance Monitoring for Continuous Improvement.

High energy consumption and desire for LEED Platinum.

35% reduction in annual energy consumption, achieved LEED Platinum, estimated 10-year ROI.

Inefficient cooling and ventilation processes and high operational costs.

20% reduction in peak cooling load, 18% reduction in operational energy costs, and improved indoor air quality.

Complex interdependencies between residential, retail, and office MEP systems; tight budget.

Eliminated 15+ major clashes pre-construction, achieved 8% project cost savings through optimised material use, and delivered 2 weeks ahead of schedule. (Adapt these with your actual or realistic project examples)

Deep knowledge in engineering optimisation, MEP systems, and sustainability.

We see the interconnectedness of systems, not just individual components.

Our recommendations are backed by rigorous analysis and quantifiable results.

We tailor solutions to your goals, budget, and project context.

Delivering measurable value in energy savings, cost reduction, and environmental performance.

We work effectively with your existing teams and consultants.

As MaSet Group prepares for an exciting future, we invite you to join our expanding network. Whether you’re an entrepreneur looking to build a successful business, a creative professional seeking collaboration, or a client ready to elevate your personal and professional brand, MaSet Group is here to turn your vision into reality.

Get a free, no-commitment consultation today.